Oldtymestockings English

Sock Machine Museum

|

|

|

|

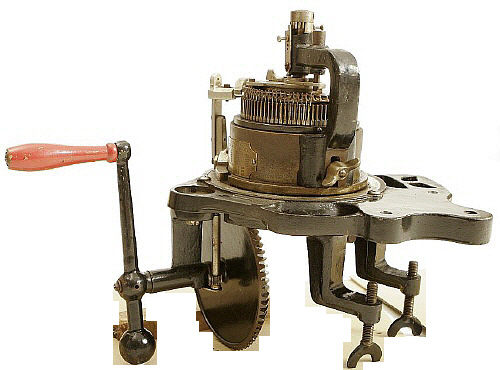

Auto Knitter Knitting Machine

Made in Leicester, England, this

sock machine's outfit included a 30 slot ribber dial and 60

slot cylinder. Although quite similar to the Canadian and

American Auto Knitters, this English sock machine is

strikingly different. Cam shells and cylinder tension

mechanisms were made of of solid iron. Ribbers and

cylinders were composed of solid steel, not pot metal or

aluminum. Yarn carriers and tappet plates were styled after

the Creelman and Legare sock knitting machines. Note that

the large ribber arm pin is on the right (New Improved

Canadian Automatic Knitting Machines), not the left (Legares,

Creelmans and Canadian/American Auto Knitters).

|

|

|

|

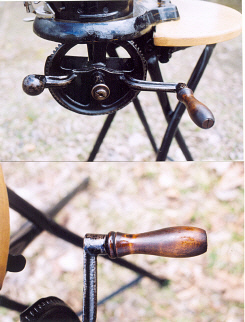

Auto Knitter Knitting Machine -

Vintage

Manufactured in England from the earliest patents, this

English sock machine is one of the oldest in the series of

Auto Knitters. The rectangular shaped ribber arm,

beveled crank wheel, detachable needle holders, cloverleaf

base and yarn carrier are hallmarks of English engineering.

Note the shape and design of the accessories. Despite

the advancement of technology, few changes in their

construction were undertaken. The English Auto Knitter

was constructed of cast iron, steel and brass. It came

standard with 30/60 and 40/80 combinations. |

|

|

|

Cymbal Circular Knitting Machine

Manufactured in Newcastle Upon

Tyne, the Cymbal sock machine came complete with solid brass

accessories and 5 pounds of wool. A 42 slot ribber

dial and 84 slot cylinder accompanied each Cymbal knitting

machine.

|

|

|

|

Foster Star Nº2 Circular

Knitting Machine

The Star Nº2 circular knitting

machine was produced by

English inventor

James Foster of Friargate, Preston. This 4¼ sock

machine came standard with a 36 slot ribber dial and a 72

slot cylinder. |

|

|

|

Golden

Fleece Circular Knitting Machine

Manufactured in England, the

Golden Fleece sock machine closely resembles the Auto

Knitter sock machine in design. Parts and accessories of

Golden Fleece knitting machines were constructed of brass,

iron and chrome. A handy tabulator was built into the sock

machine to assist with row counting.

|

|

|

|

Griswold & Hainsworth Circular

Knitting Machine

Manufactured in England, this

English sock machine remains one of the oldest in existence.

Spindle shaped bobbins rotate around the cylinder whilst in

operation. Unlike the traditional horizontal

arrangement, the yarn mast stands vertical to the cylinder.

Adjustment of the ribber height is attained by untightening

a large thumb screw and lowering or raising the centre

ribber post. The unparalleled design of this English

sock machine originates from the British inventors,

Hainsworth and Griswold. |

|

|

|

Griswold Circular Knitting Machine

In England,

domestic circular knitting machines became known by the term

"Griswold", owing to Henry Josiah Griswold (1837 - 1929)

of Madison, Connecticut. In 1891, Griswold formed the

London and Leicester Hosiery Company and leased a factory on

Winifred Street in Leicester, England. Between 1890 and

1892, Griswold returned to America and sold his rights to

the firm to I. L. Berridge.

Numerous

improvements were introduced to Griswold sock machines.

Nevertheless, they remained solid. The most common setup

for Griswold sock machines was a 42 slot ribber dial and an

84 slot cylinder.

|

|

|

|

Harrison Circular Knitting Machine The

Harrison circular knitting machine was manufactured in

Manchester, England by the Harrison Patent Knitting Machine

Co. Ltd. Harrison knitting machines have the company's

emblem conspicuously stamped in their bases. A 42/84

setup came standard with each machine. Cast iron stands,

balling machines and large hand winders were available at

additional cost. At the turn of the century, the Harrison

circular knitting machine underwent a final improvement and

was termed the New Sun Circular Knitting Machine.

During their

age of manufacture, Harrison circular knitting machines

won 38 awards for superiority of construction and capacity

of work. The Harrison Patent Knitting Machine company was

the only English manufacturer of knitting machines to win 10

gold medals for craftsmanship in the knitting machine

industry. In 1908, the company was awarded the highly

acclaimed Grand Prix gold medal at the Franco-British

exhibition.

|

|

|

|

Harrison New Sunette Circular

Ribber Knitting Machine

The New Harrison Sunette

Circular Ribber sock machine was manufactured by the

Harrison Patent Knitting Machine Co. L. t. d. This

English sock machine was one of their earliest editions.

Note the sparse, golden decals along the base of the

machine; a sharp contrast to the Harrison Sun Circular

Ribbing machine. The New Sunette Circular Ribber sock

machine came standard with a 42/84 combination and an array

of knitting accessories. |

|

|

|

Harrison Sun Circular 3½ Knitting Machine

Harrison Sun Circular machines were manufactured in 3½, 3¾,

and 4 inch diameters for baby and infant stockings.

Harrison Sun Circular 3½ sock machines came standard with

36/72 or 42/84 combinations. Like Harrison's standard

4½ diameter Sun Circular Ribbing machines, the 3½ Sun

Circular Ribbing machines were composed of cast iron, steel

and brass. |

|

|

|

Harrison Sun Circular Ribbing Machine

The Harrison Sun Circular Sock

Machines were notable for the conspicuous golden decals along their bases and

ribber arms. In addition, the firm routinely engraved

their name into the base plates of their knitting machines.

Known the world over for outstanding engineering, the

Harrison Knitting Machine company produced a catalog of

circular and flat bed knitting machines for domestic and

commercial trade. |

|

|

|

Imperia Circular Knitting

Machine

Well known for its unique design, this English sock

machine displayed a solid brass counter that operated in

forward and reverse. Parts of this sock machine were

composed of solid chrome and iron. Alignment of the ribber

dial was accomplished by rotating a lever on the left side

of the sock machine which attached directly to the

cylinder. This lever enabled the ribber to rotate

backwards and forwards. The shape of the yarn mast

replicates the royal order in moderate fashion. Its 42 slot

ribber and 84 slot cylinder were popular for gentlemen's

trouser hose and ladies' saxony hosiery.

|

|

|

|

Imperia Circular Knitting Machine - Quadruplex

Imperia's

Quadruplex

sock machine included many of the ribber dial and cylinder

combinations produced by the company. Imperia's Quadruplex

model enabled the production of fine, saxony hosiery, as

well as conventional trouser socks. The Quadruplex

model was well-suited for commercial knitting or retail

trade. Ribber dial and cylinder outfits of 36/72, 42/84, 54/108 and

60/120 came standard with Imperia's Quadruplex model.

|

|

|

|

Imperia Circular Knitting Machine - Triplex

The Triplex

Imperia sock machine was commonly used to produce argyle

stockings, saxony hosiery and fine knitwear due to its high

slot counts. The Triplex Imperia sock machine featured ribber dial and cylinder outfits of 36/72, 42/84

and 54/108. The 42/84 combination is shown inside the

machine.

|

|

|

London Knitting Machine Company Duplex

Knitting Machine

Known for its |

|

|

Victoria Automatic Improved Knitting Machine

Manufactured by

W & J Foster, this English sock knitting machine is one of

their later versions. The Victoria

Automatic Knitting machines featured solid brass ribber

dials, brass counters, brass cylinder belts, brass wing nuts

and brass set up umbrellas. Their design approximates the

Griswold circular knitting machines. As with most English

circular knitting machines, a 42/84 set up was standard.

|

|

|

|

Victoria Automatic Knitting Machine

Manufactured by W & J Foster, this English sock knitting

machine is an early edition. Victoria Automatic

Knitting machines had the capability of accommodating duplex

cylinders. Note the two part yarn carrier.

Parallel screws allow proper alignment to various cylinder

sizes.

Duplex cylinders have diameters of 3¼, 3½ or 3¾ inches and

readily interchange with standard 4½ inch diameter cam

shells. In this fashion, ribbed, seamless socks for

babies and children could be knitted quite easily. Duplex

machines came standard with a 42/84, 4½ inch diameter

combination and a 36/72, 3¾ inch diameter combination.

|

|

|

|

Victoria Automatic Knitting Machine

The influence of regality

and sovereignty is readily demonstrated in the Victoria

Automatic Knitting machine. Manufactured in London,

England, the base of the Victoria sock machine replicates

the contour of the royal crown. Note the queen like quality

of the yarn mast. Solid brass ribber dials, cylinder belts

and row counters impart a majestic impression.

|

|

|

|

|

|